CUSTOM DRUM DUMPER WITH SPIN AND WASH CAPABILITY

DUMPING STICKY METAL PARTS TO A WASHER SYSTEM

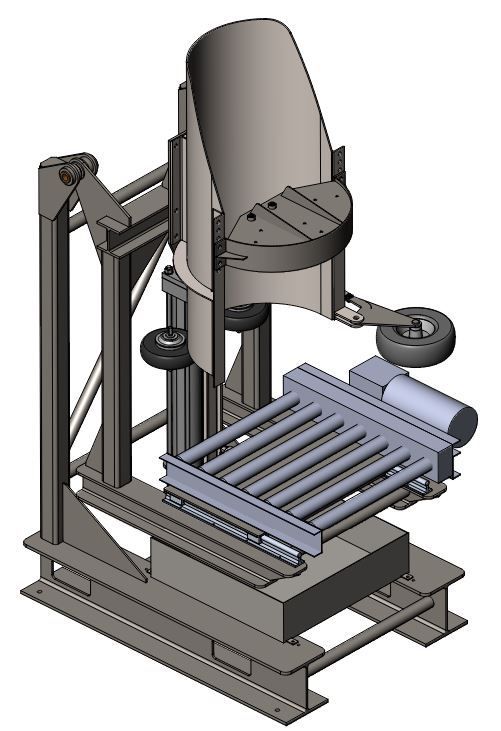

Matrix designed, supplied and installed a turnkey custom drum dumper for COMPLETELY DISCHARGING OILY, STICKY metal parts to a washing system.

This process automated a formerly labor intensive process in which an operator was responsible for dumping and elevating each drum individually. The parts were so sticky, the operator was require to use a hand brush to clean out each drum onto a an elevating conveyor. These various small metal parts also had to be brushed off of the elevating conveyor at the end of each drum batch. These parts also tended to hang in the conveyor and cause maintenance issues.

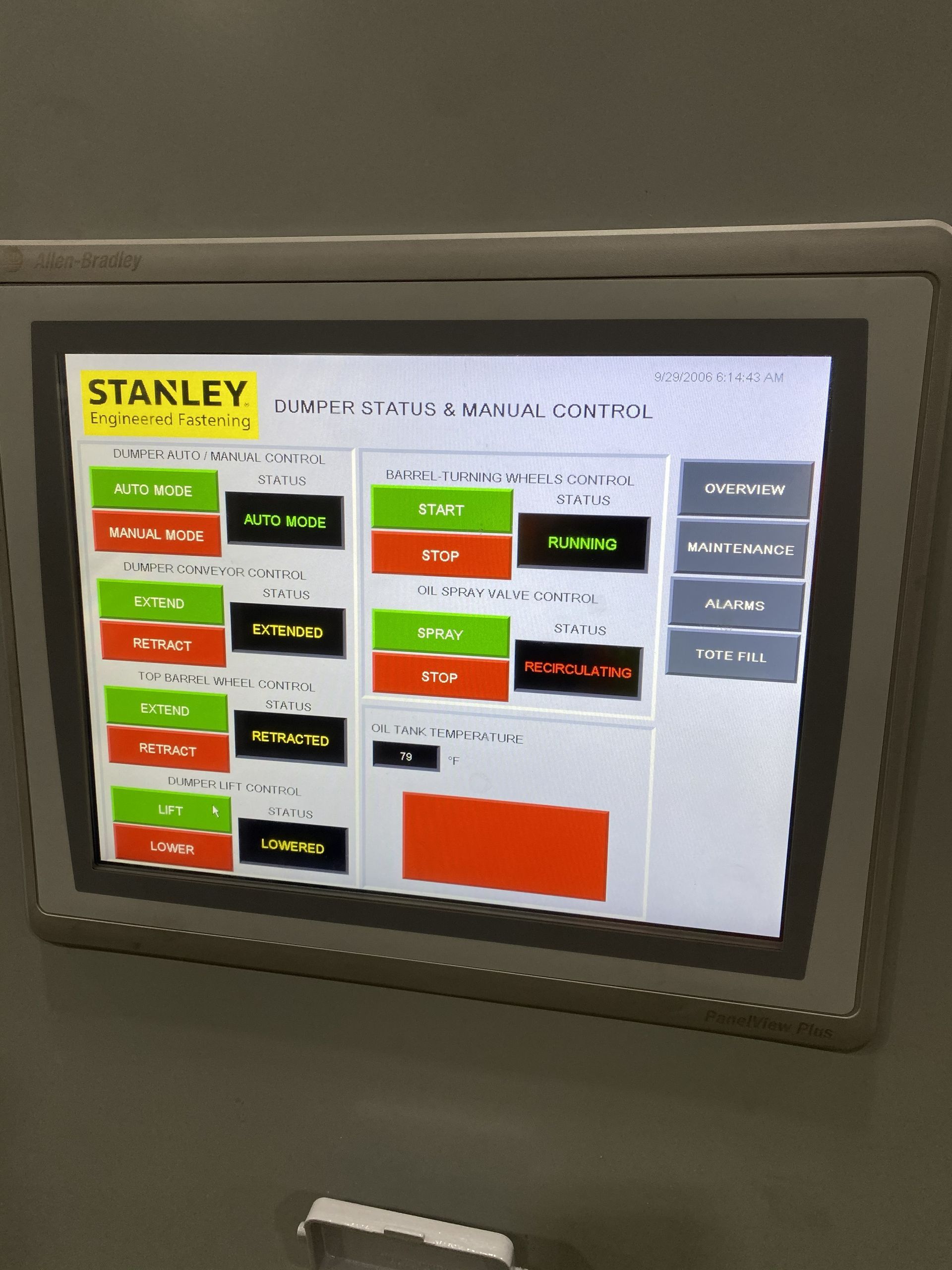

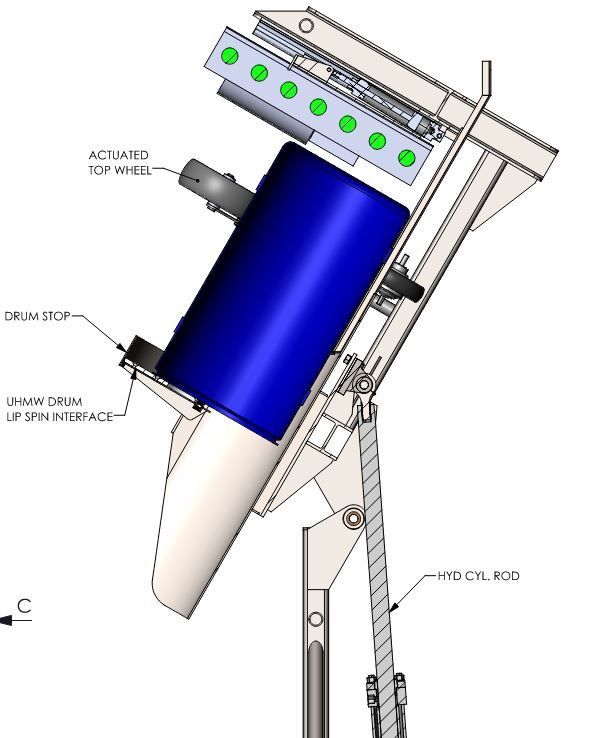

The Matrix design solution consisted of a steep tilt 60deg dumper that was capable of spinning and washing out in the lifted position. We also utilized a dump chute with a rough sheet finish to prevent surface tension sticking of the oily parts. For the drum wash out system we provided a recycle tank from the upstream wash process with a pump and spray wash nozzle to the drum interior.

This system was fully automated with the ability to self load and unload from our drum handling roller conveyor system also provided by Matrix.