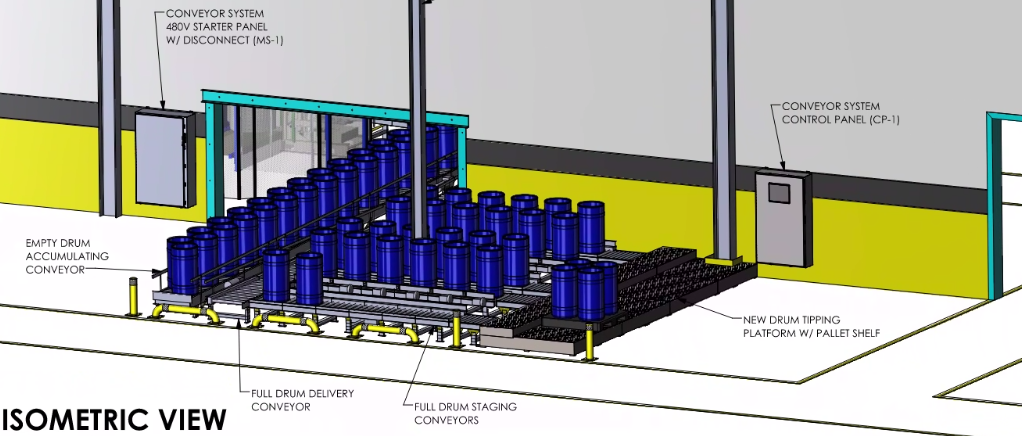

DRUM STAGING, INDEXING AND TRANSFER SYSTEM

METAL PART DRUMS TO WASHING SYSTEM AND TRANSFER TO TOTES

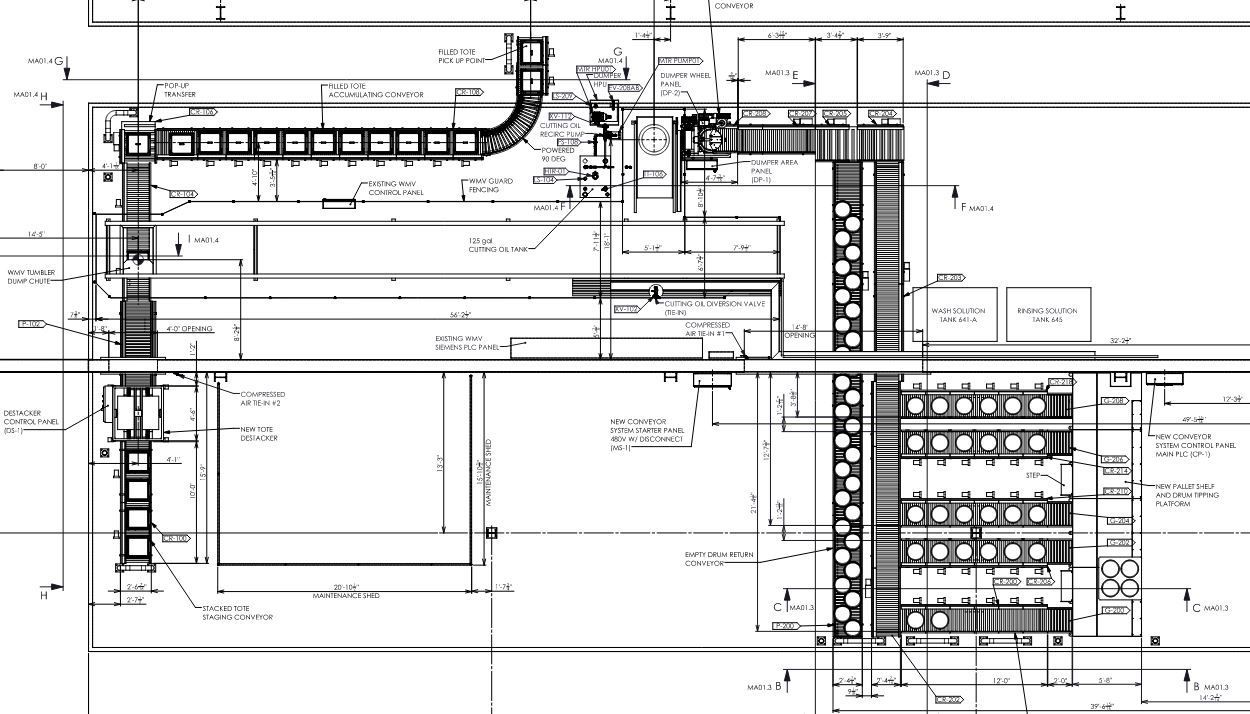

Matrix designed and supplied a drum based material handling system for transferring various metal parts/fasteners to a washing system. Our system also handled the washed parts after transferring them to smaller totes to be used in the downstream process. Our system was capable of staging 30 filled drums with a variety of different possible parts. Our filled drum infeed system utilized a PLC with wireless barcode scanning to track each batch of parts being washed and subsequently printed a barcode data sheet dropping it in each of the washed parts finished totes at the end of the system.

This process automated a formerly labor intensive process in which an operator was responsible for dumping and elevating each drum individually. With our system, the operator was able to efficiently load the indexing conveyors, quickly barcode scan them in place and walk away from the system and perform other duties.

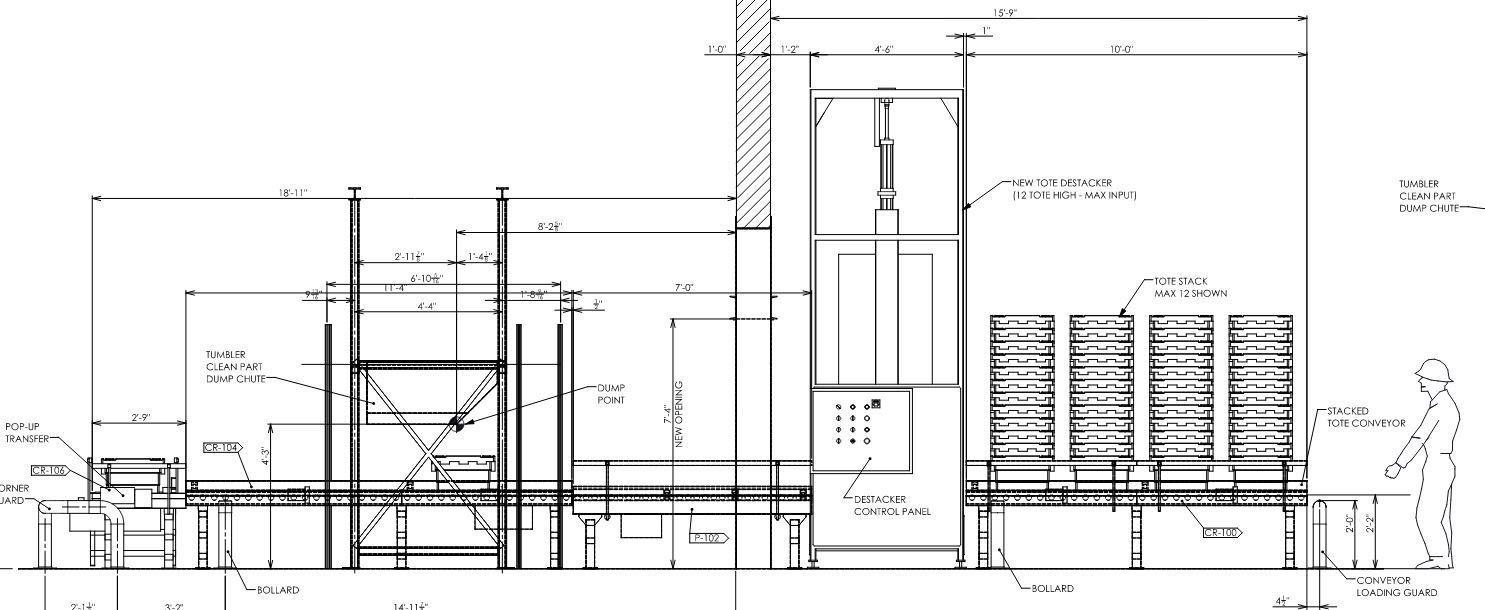

On the discharge side of the washing system, we utilized a "tote de-stacker" to store and index totes into the catch-out process. After the Totes where filled with clean parts, they went to automated indexing conveyors for ultimate removal with a fork truck.