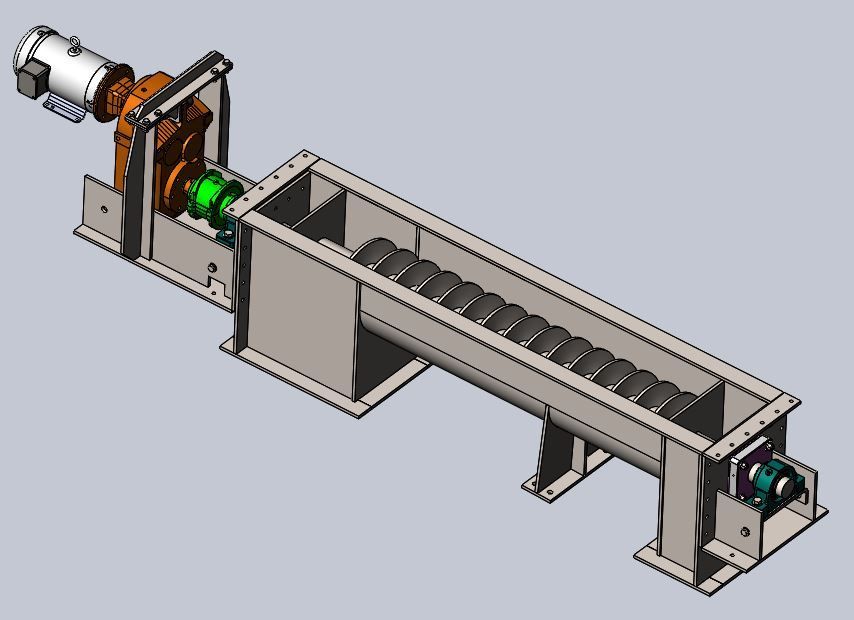

Barge Cover Production Gantry System with 7-Axis Servo Control

Matrix Industrial Systems provided the complete control system with necessary programming and HMI integration for two large scale production units that perform plastic spray molding of barge covers.

We provided two cabinets for control of each individual spray molding system with one AB ControlLogix processor and remote I/O all communicating on a common Ethernet ring. We provided Rockwell Servo Motors and high resolution multi-turn encoders for positional tracking of each motion axis along with AB Kinetix 6500 Servo Controllers with safe stop modules. We also provided the complete PC based SCADA system with historian for recording batch information for each cover.

We programmed 4 linear axes on each machine for horizontal and vertical translation of three rotary axes through a given mold profile. The gantry would apply three different material coats through 18 spray guns on at a controlled velocity for a repeatable thickness of the plastic covering based on the consistent application of the polyethylene powder. One of the machines took care of the outer profile of the barge cover, while the other gantry machine was programmed for the inner profile on the same cover. The environment was harsh and dirty with room temperatures in excess of 150F.

More Projects & News