Projects

Machine Design, Modeling and FEA Services

A general description of this category of projects.

01 Dec, 2021

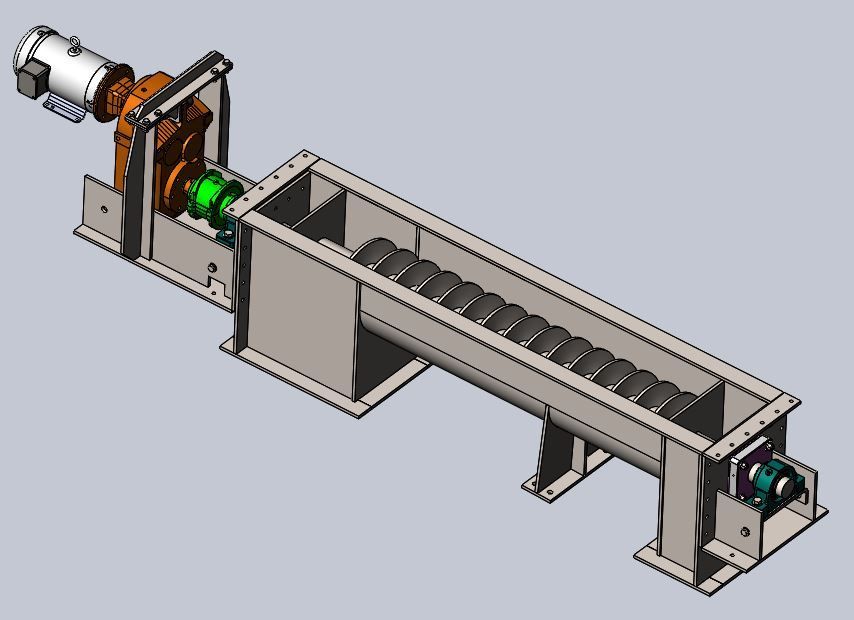

Matrix provided conceptual and hard mechanical design of a heavy duty screw feeder for metering phosphorus pentoxide (crystallized phosphoric acid) into a dissolve tank. Due to the hot reaction during hydration in the tank (resulting into very hot phosphoric acid) the variable speed screw feeder consisted of a 316L S/S 12 inch diameter auger and 1/2 inch thick trough. A special dump hopper with automated closing lid was designed with a large grated opening and bypass chute at the inlet of the feeder. Very special design considerations were made for protecting the conveyor seals and bearings from making contact with the hot acid. Our design allowed the acid crystals or hot liquid to fall out into an isolated gap and into the tank before it challenged the seal. This was a highly successful design has virtually eliminated the huge stock piles of drummed feedback material that accumulated due to the inability to dissolve the crystallized acid safely.

By Darren Jarvis

•

02 Dec, 2018

Matrix along with our partner, AC Plus Marine, have developed a revolutionary new hot water system for the diving industry. THERMO-DIVE is an all-electric system that uses 75% less power than standard electric systems with heating elements. Matrix has developed several different models for offshore as well as inland applications.

By Darren Jarvis

•

09 May, 2016

Matrix along with our partner, AC Plus Marine, engineered a Launch and Recovery System (LARS) for offshore diving, inspection and maintenance of the Shell Stones Turritella. We performed this contract under the Southern Crane and Hydraulics who fabricated, assembled and delivered the unit for lease by Royal Dutch Shell. This LARS was unique among its kind in order to meet the requirements on the Turritella. It need to be easily assembled, disassembled and compactly stowed on the vessel for deployment in 12 different locations. The LARS was engineered for 4400lb Allowable Lift at (2g/1g/1g) requirements and was American Board of Shipping (ABS) Surveyed, Approved and Certified for use.

By Darren Jarvis

•

01 Mar, 2016

Matrix along with our partner, AC Plus Marine, engineered a hydraulic operated man-rated winch for use on Launch and Recovery Systems (LARS). We performed this contract under the Southern Crane and Hydraulics who is licensed to build these winches. AC Marine conceived and shepherded the design and build through the American Board of Shipping (ABS) Certification process. To our knowledge, these are the only Dual Brake Man Rated Winches that have been certified by ABS.

02 Mar, 2006

Matrix provided the mechanical design for custom design of a sanitary u-bend at the bottom of an existing spray dryer. The u-bend had to be dis-assembled and cleaned frequently for product changeovers. Our sanitary design allowed for quick and easy cleaning by rolling back half the u-bend on a track and rotating the other half on a pivot bearing. Not only did the tool-less design provide ease dis-assembly and assembly, but it also provided a superior o-ring seal over the previous arrangement. This is extremely beneficial for a vacuum system handling a glue-like powder that is seeking moisture. Our design substantially reduced product build-up between cleanings and allowed viewing of operation and status with a properly positioned viewport and light.

01 Mar, 1996

Matrix provided the mechanical and structural engineering necessary for analyzing and repairing an existing dumper after a catastrophic failure. The dumper handled a 6000 lb payload and was originally designed by another vendor. Due to our quick response, very little production time was lost.

01 Feb, 1996

Matrix Engineering provided the detailed fabrication and design drawings of an auger feeder/dryer for processing a catalyst paste prior to pelletizing. The unit employed a hot air jacket for drying and an adjustable weir plate for retention time. The unit was also given wheels for use in easy removal when performing maintenance on area equipment.

02 Dec, 1995

Matrix performed finite element analysis on a new and improved sanitary cure bin at US Smokeless Tobacco. The cure bins hold approximately 5000 lb of product. They are trucked around the facility quite frequently and see some fairly rough treatment. The analysis allowed optimization of the sanitary design while maintaining and improving structural characteristics.

Site Map

Contact Info

112 Walter Jetton BlvdPaducah, KY 42001, United States

Website Design & Hosting by Arterburn.com