Projects

Marine Systems

Matrix Engineering and Matrix Industrial Systems have developed a strong foothold in marine projects. From Aquariums and Inland Waterways to Offshore Projects, call on Matrix for your design support.

By Darren Jarvis

•

03 Jan, 2021

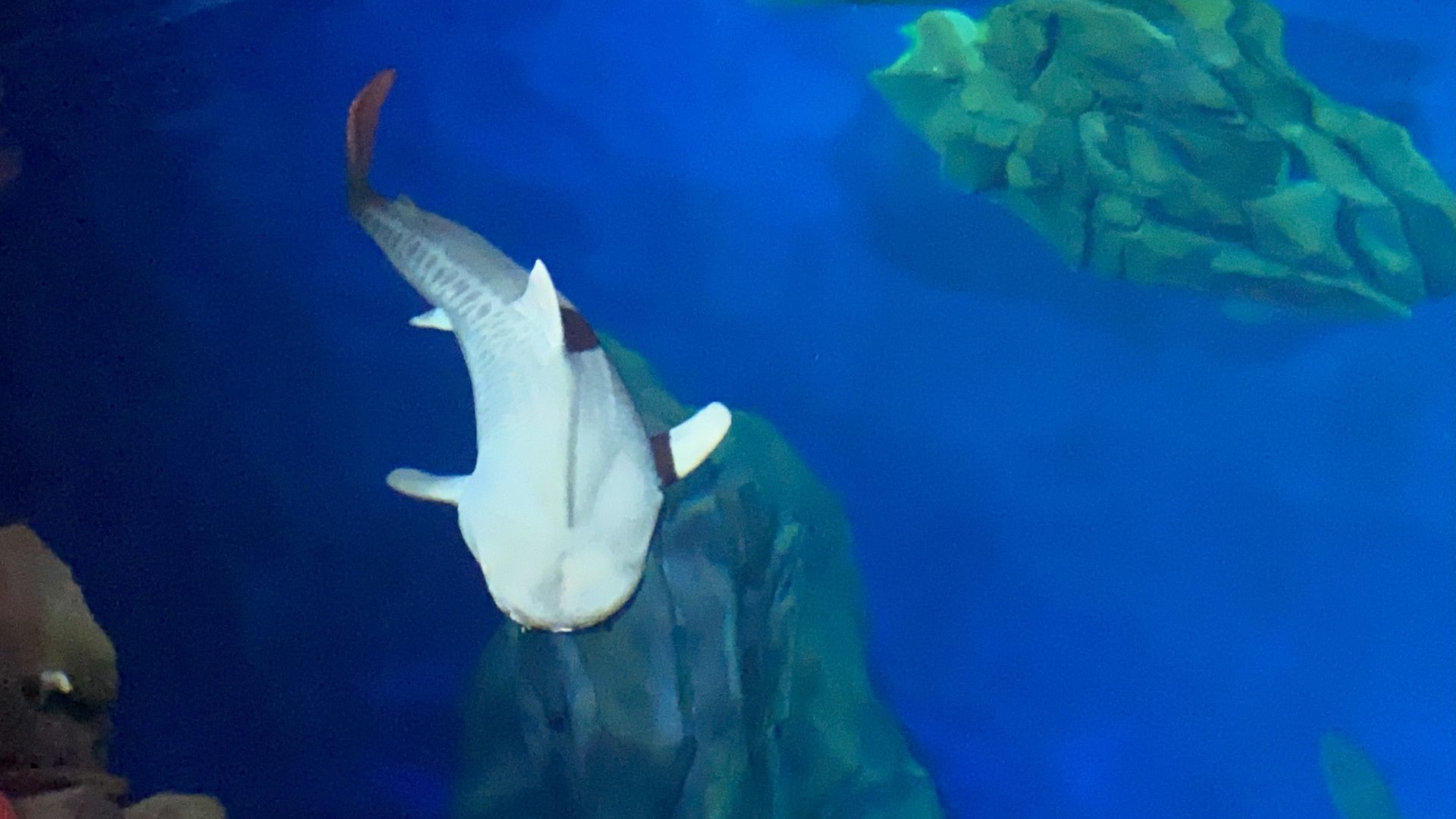

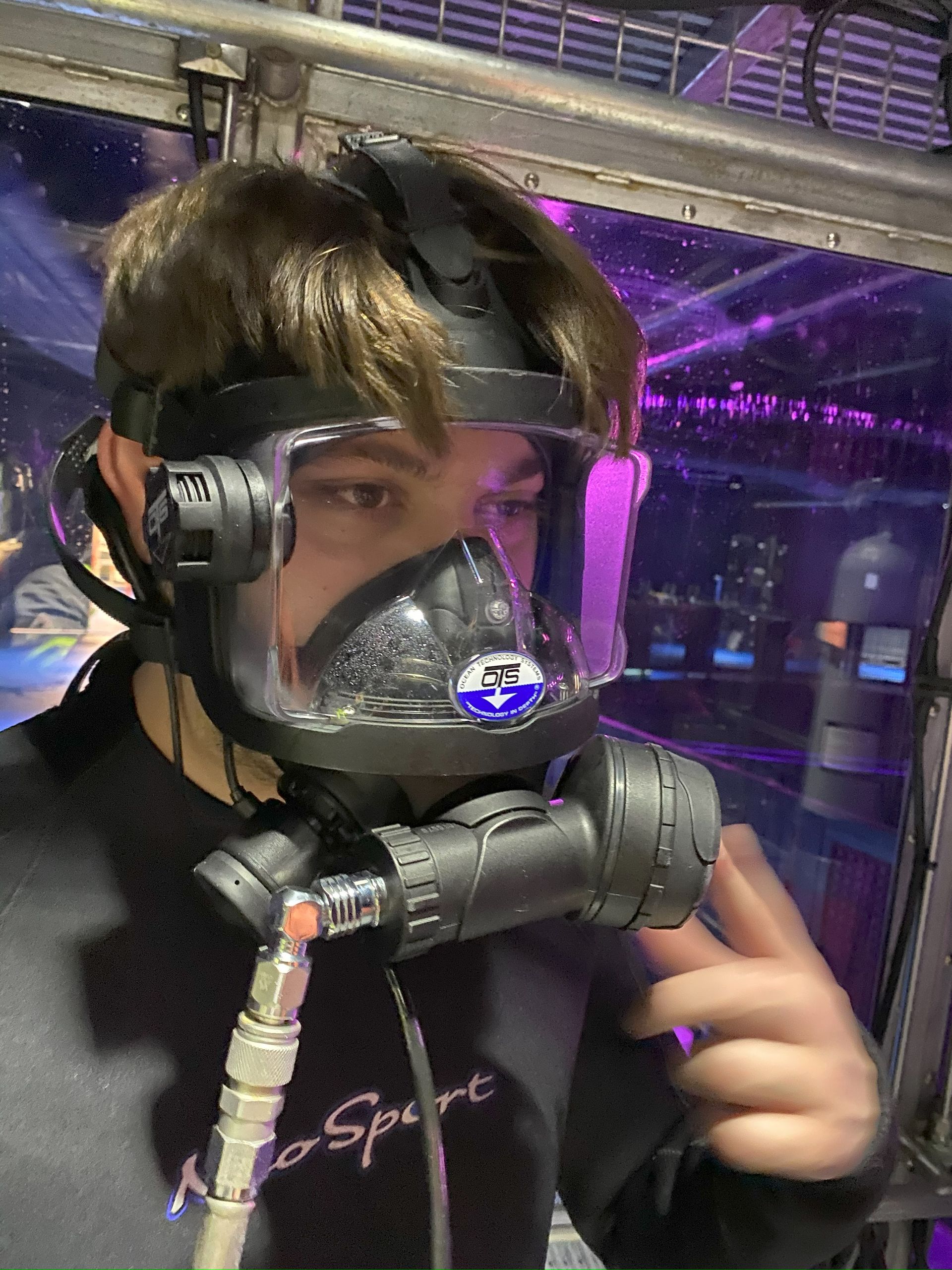

Matrix Industrial Systems was proud to work in conjunction with AC Marine in designing and supplying critical systems for Georgia Aquarium's newest venue to experience sharks directly with the grand opening of their 1.2MM gallon Shark Tank. This attraction allows you to submerge into the tank within a shark cage and begin an underwater journey traversing the pool as it is suspended and moved by a hoist/monorail system. Breathing air for the participants is supplied through an umbilical tethered to the cage and connected to a specialized Breathing Air Control System (BACS). Matrix supplied and installed this system with its umbilical as a turnkey project. Matrix and AC Marine were proud to be guinea pigs (or should I say SHARK BAIT) on the maiden voyage!

By Darren Jarvis

•

21 Dec, 2020

Matrix Industrial Systems was proud to work in conjunction with AC Marine in designing and supplying critical systems for Georgia Aquarium's newest venue to experience sharks directly with the grand opening of their 1.2MM gallon Shark Tank. This attraction allows you to submerge into the tank within a shark cage and begin an underwater journey traversing the pool as it is suspended and moved by a hoist/monorail system. Breathing air for the participants is supplied through an umbilical tethered to the cage and connected to a specialized Breathing Air Control System (BACS). Matrix designed, supplied and installed the complete BACS. Our system incorporated many levels of redundancy and failsafe design on the shore as well as in the cage itself. We deploy a 2-stage primary breathing air compressor with a secondary 2-stage back-up. In the event that all 4 stages were to fail and the system pressure dropped below setpoint (or a major power failure), then we have emergency shore supplied high pressure K-bottles that automatically deploy to maintain the air supply. On top of that, if breathing air pressure within cage itself were to drop too low (either complete failure from shore or if the umbilical became detached from the cage) then we designed another high pressure emergency air supply within the cage itself. This system was completely mechanical in nature bolstering a failsafe independent system design. Matrix's project scope was as follows: Engineer and HAZOP the complete sanitary breathing air system as a life safety critical system. Supply and Install the BACS as a complete Equipment Package. Supply and Install the PLC Based Control System for the BACS as a UL Certified 508A Control System. Supply and Install the Umbilical, Festoon System and Connections to Shore and Cage. Supply and Install the Cage Breathing Air Manifold and Components.

By Darren Jarvis

•

02 Dec, 2018

Matrix along with our partner, AC Plus Marine, have developed a revolutionary new hot water system for the diving industry. THERMO-DIVE is an all-electric system that uses 75% less power than standard electric systems with heating elements. Matrix has developed several different models for offshore as well as inland applications.

By Darren Jarvis

•

09 May, 2016

Matrix along with our partner, AC Plus Marine, engineered a Launch and Recovery System (LARS) for offshore diving, inspection and maintenance of the Shell Stones Turritella. We performed this contract under the Southern Crane and Hydraulics who fabricated, assembled and delivered the unit for lease by Royal Dutch Shell. This LARS was unique among its kind in order to meet the requirements on the Turritella. It need to be easily assembled, disassembled and compactly stowed on the vessel for deployment in 12 different locations. The LARS was engineered for 4400lb Allowable Lift at (2g/1g/1g) requirements and was American Board of Shipping (ABS) Surveyed, Approved and Certified for use.

By Darren Jarvis

•

01 Mar, 2016

Matrix along with our partner, AC Plus Marine, engineered a hydraulic operated man-rated winch for use on Launch and Recovery Systems (LARS). We performed this contract under the Southern Crane and Hydraulics who is licensed to build these winches. AC Marine conceived and shepherded the design and build through the American Board of Shipping (ABS) Certification process. To our knowledge, these are the only Dual Brake Man Rated Winches that have been certified by ABS.

15 Dec, 2011

Matrix Industrial Systems provided all hardware and PLC programming for a barge positioning system used for loading and unloading barges without assistance from a tugboat. The control system included 2 VFD’s, one controlling a winch on the bow of the barge, the other on the stern. Our control system adjusted tension on both winches to balance and position the barge.

Site Map

Contact Info

112 Walter Jetton BlvdPaducah, KY 42001, United States

Website Design & Hosting by Arterburn.com