LIFT & RECOVERY SYSTEM (LARS) FOR SHELL STONES PROJECT

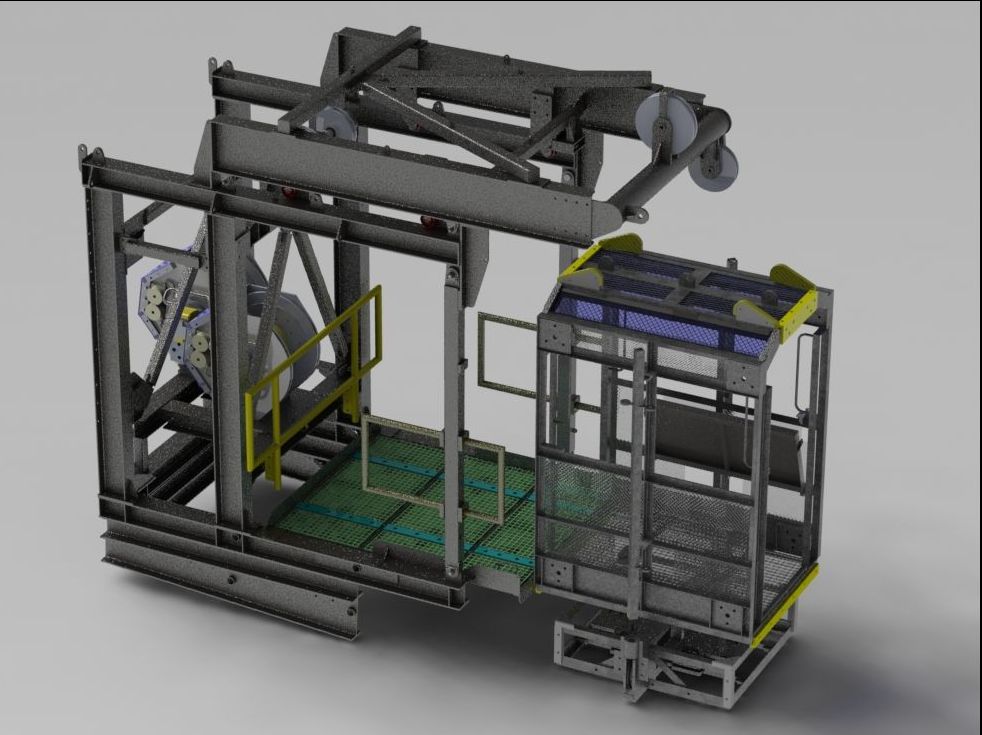

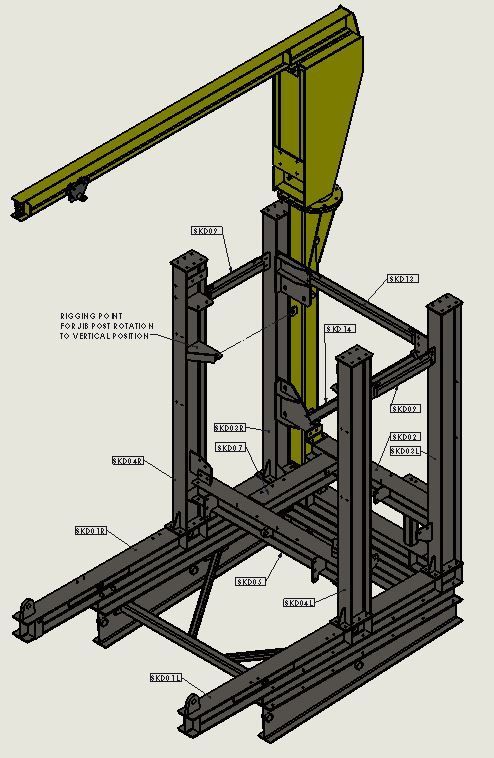

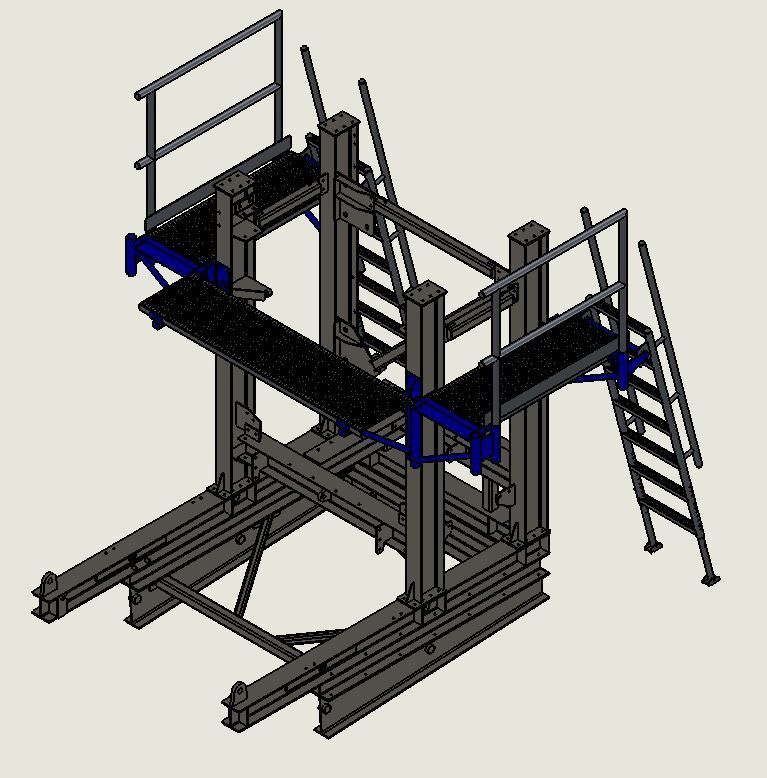

Matrix along with our partner, AC Plus Marine, engineered a Launch and Recovery System (LARS) for offshore diving, inspection and maintenance of the Shell Stones Turritella. We performed this contract under the Southern Crane and Hydraulics who fabricated, assembled and delivered the unit for lease by Royal Dutch Shell. This LARS was unique among its kind in order to meet the requirements on the Turritella. It need to be easily assembled, disassembled and compactly stowed on the vessel for deployment in 12 different locations.

The LARS was engineered for 4400lb Allowable Lift at (2g/1g/1g) requirements and was American Board of Shipping (ABS) Surveyed, Approved and Certified for use.

Slide title

Write your caption hereButtonSlide title

Write your caption hereButtonSlide title

Write your caption hereButton

Slide title

Write your caption hereButton

The LARS design was optimized for member weight and included a tilt-up jib for "self-erection" along with custom designed scaffolding used in its final assembly and inspection.

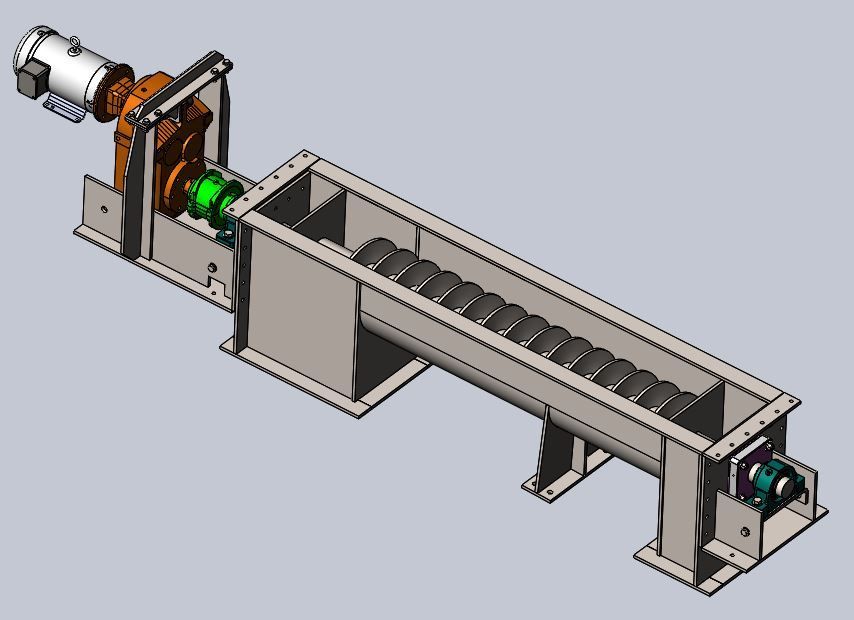

The LARS was equipped with (2) hydraulic powered MAN-RATED winches that were also conceived and specified by AC Marine and fully engineered by Matrix. These winches were also ABS Certified.

Below are fabrication photos from Southern Crane's shop in Houma, LA.

More Projects & News