BOGALUSA, LOUISIANA - Salt Cake Feed and Convey System

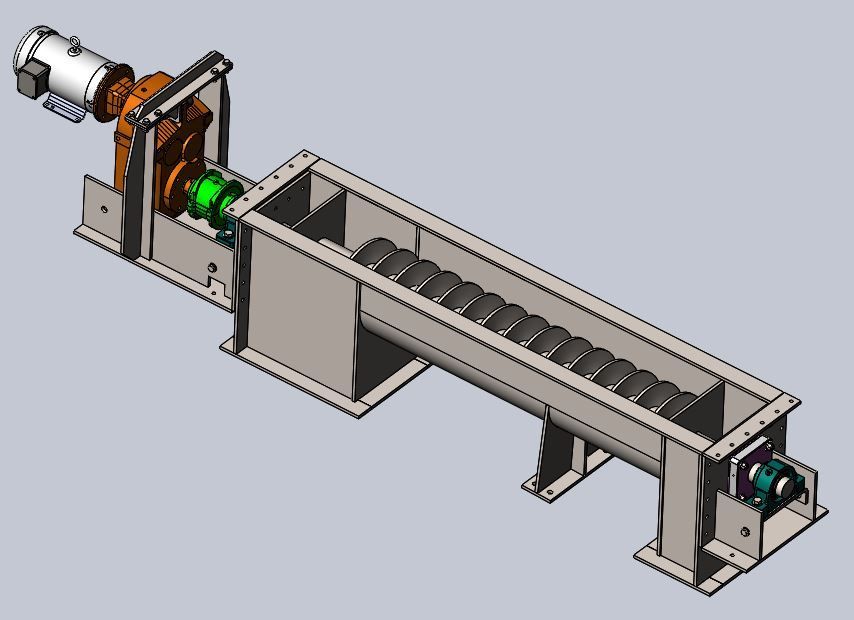

Matrix Industrial Systems provided the engineering and equipment supply for adding a new destination to an existing salt cake feed and convey system at the Temple-Inland Bogalusa Mill.

In order to avoid the extreme cost and lead time of a new independent salt cake storage and feed system, Temple-Inland called Matrix for assistance in modifying their existing salt cake storage system to handle an additional destination. They wanted the flexibility of additional salt cake in their black liquor mix tank on their second recovery boiler. However it was over 250 ft away from their existing salt cake storage. This was coupled with the need to install the new system within 8 weeks of initiation of contact with Matrix. Therefore we had to act quickly to engineer and supply the system to meet their needs in spite of their spatial and time constraints.

Matrix supplied a dual rotary valve arrangement. The upper airlock was a custom Matrix feeder and the lower airlock was the transfer conveyor to the pneumatic system. Our rotary valve feeder was very consistent and repeatable capable of a 10:1 turndown ranging from 1.3 tpd to 13 tpd. Our rotary valves were designed for extreme service with high-torque extra heavy duty drives and hardened rotors.

From this point, utilized a PD blower to convey the material over 250 ft to a Matrix custom designed cyclone and material release hopper above the salt cake mix tank. Transferring the salt cake to the mix tank required special design consideration to avoid getting moisture into the cyclone or clogging the chute.

More Projects & News