LIFT STATION CONTROLS UPGRADE & ELECTRICAL MODERNIZATION

Matrix Engineering provided the electrical design and implementation of a new MCC, PLC panel and an automatic Auxiliary Power system for the Paducah McCracken JSA Husband Street Lift Station. The new MCC and PLC panel were designed and installed to replace outdated technology to provide a more reliable, operator friendly, and efficient operating lift station.

The control system was designed to operate (3) 15 HP pumps, (2) 1 HP seal pumps, level control, and (3) magnetic flowmeters. The PLC panel was equipped with an HMI Operator Interface to allow control of the station in Manual or Automatic mode.

A new 175kW auxiliary power system was sized and installed to provide continuous operation of the lift station during power outages. The auxiliary power system was equipped with a 225 Amp automatic transfer switch which allowed for seamless power transfer. The lift station was connected to an auto dial Verbatim System for alarm situations. The station was connected to an existing SCADA system, also developed by Matrix.

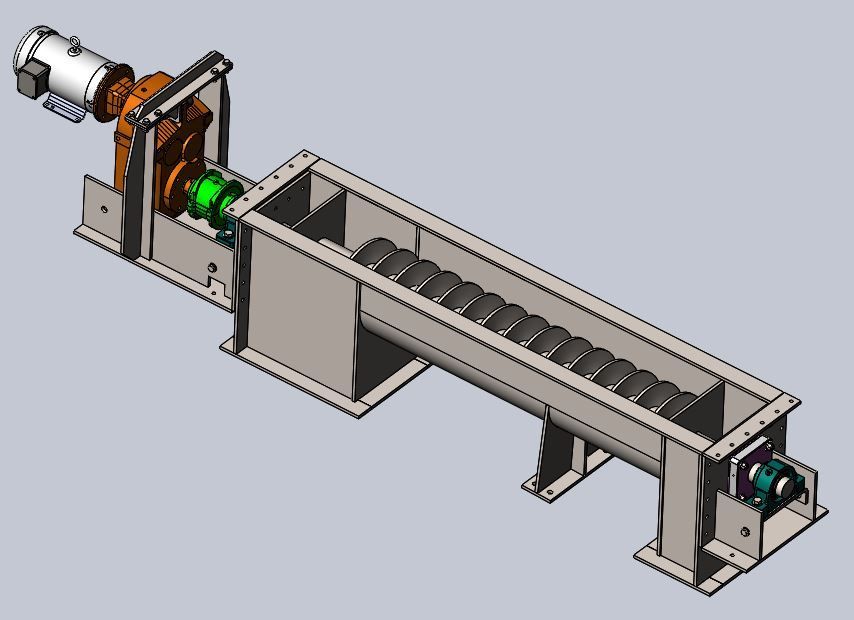

We also provided the structural support design and implementation of a new Muffin Monster for the Husband Street lift station. The new Muffin Monster was implemented to allow for solids reduction and minimize the chance of clogging pumps. A new stainless steel structural support track system was designed along with a new motorized retrieval hoist for the new Muffin Monster for ease of maintenance.

More Projects & News