MATRIX PROJECTS

MONOCAL STORAGE & DISTRIBUTION

Jan 15, 2003

Matrix provided the structural, mechanical, electrical and controls expertise in designing a product blending, storage and convey system for a leavening acid used in the baking industry. The new system replaced existing mechanical screw conveyors and elevators with pneumatic blenders, transporters, mass flow silos and a modernized control system. This new equipment included a bulk bag unloading system and transporter for conveying a flow agent to two different locations where it is added and blended to different monocals.

A surge hopper was installed at the end of the monocalcium production process. The flow agent is added gravimetrically below this hopper and blended using an air blender/transporter.

From this location the monocal is conveyed to 250,000lb mass flow silo (with load cell package). From the silo the product is dense phase conveyed to two possible receiving hoppers above a packaging area.

We also engineered rework stations for feeding back both 50 lb bags and bulk bags into the final blending and packaging system. As a part of this project we also completely upgraded the controls for the monocal mixing and packaging system with large screen graphical operator interfaces. We also designed a new MCC room to accommodate this modernization project.

More Projects & News

01 Dec, 2021

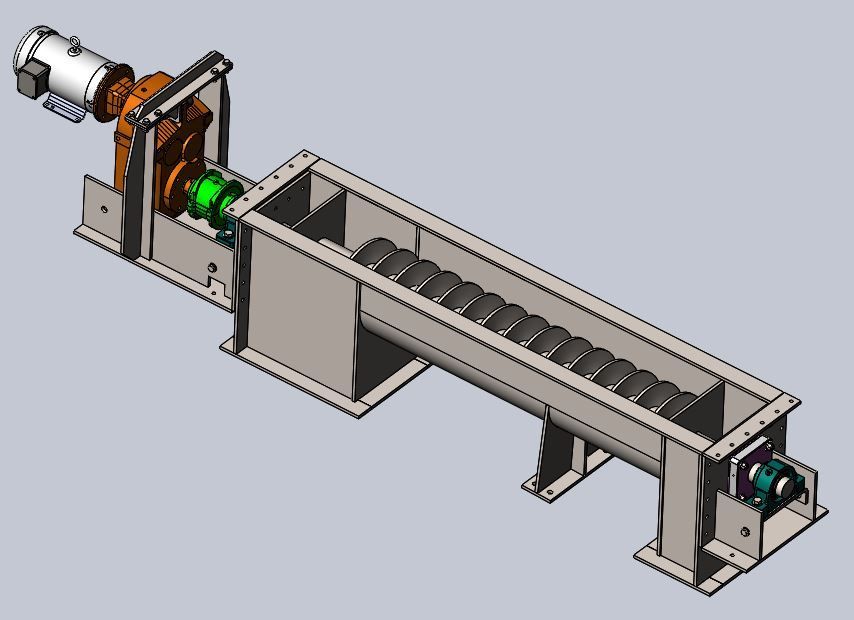

Matrix provided conceptual and hard mechanical design of a heavy duty screw feeder for metering phosphorus pentoxide (crystallized phosphoric acid) into a dissolve tank. Due to the hot reaction during hydration in the tank (resulting into very hot phosphoric acid) the variable speed screw feeder consisted of a 316L S/S 12 inch diameter auger and 1/2 inch thick trough. A special dump hopper with automated closing lid was designed with a large grated opening and bypass chute at the inlet of the feeder. Very special design considerations were made for protecting the conveyor seals and bearings from making contact with the hot acid. Our design allowed the acid crystals or hot liquid to fall out into an isolated gap and into the tank before it challenged the seal. This was a highly successful design has virtually eliminated the huge stock piles of drummed feedback material that accumulated due to the inability to dissolve the crystallized acid safely.

By Darren Jarvis

•

03 Jan, 2021

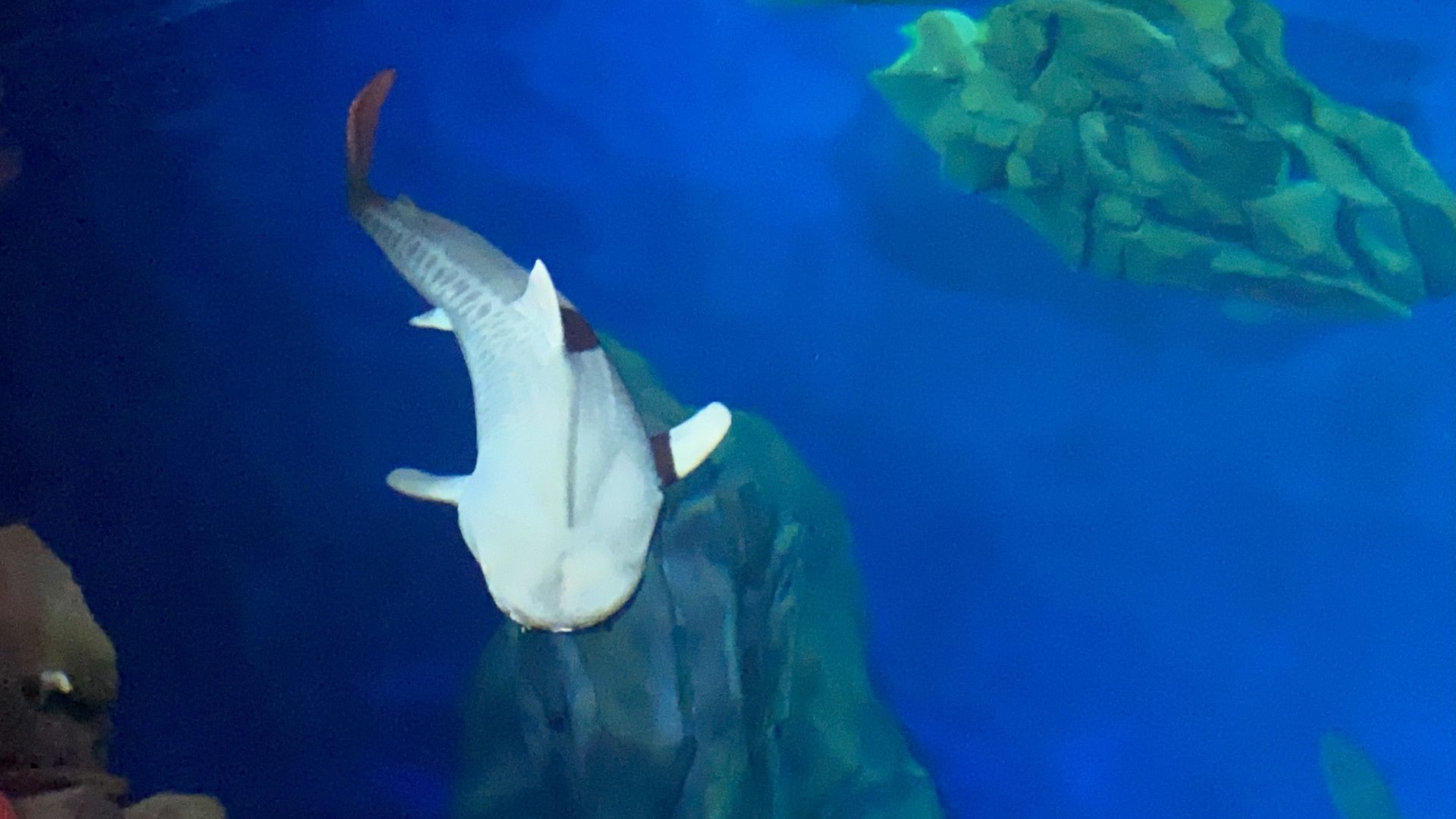

Matrix Industrial Systems was proud to work in conjunction with AC Marine in designing and supplying critical systems for Georgia Aquarium's newest venue to experience sharks directly with the grand opening of their 1.2MM gallon Shark Tank. This attraction allows you to submerge into the tank within a shark cage and begin an underwater journey traversing the pool as it is suspended and moved by a hoist/monorail system. Breathing air for the participants is supplied through an umbilical tethered to the cage and connected to a specialized Breathing Air Control System (BACS). Matrix supplied and installed this system with its umbilical as a turnkey project. Matrix and AC Marine were proud to be guinea pigs (or should I say SHARK BAIT) on the maiden voyage!

Site Map

Contact Info

112 Walter Jetton BlvdPaducah, KY 42001, United States

Website Design & Hosting by Arterburn.com