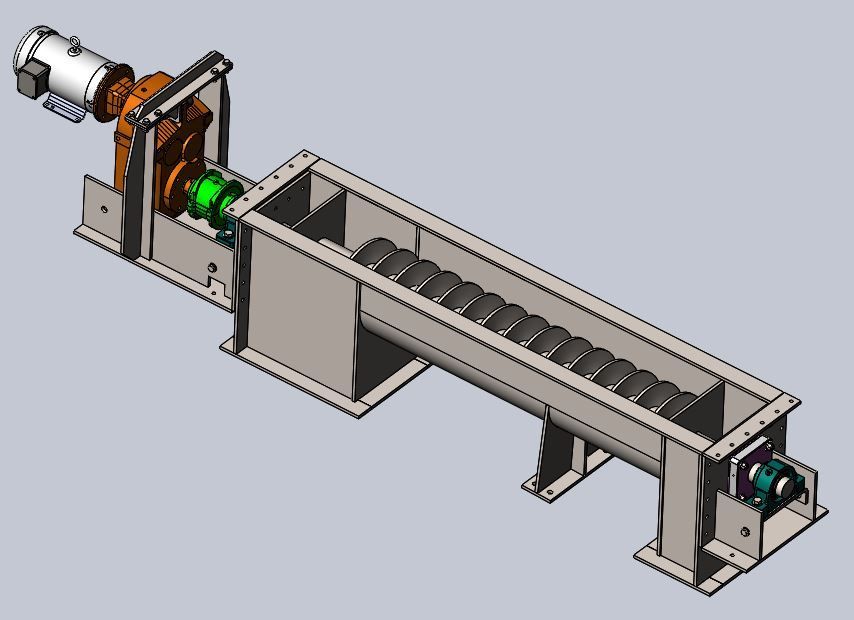

WATER TREATMENT AREA - CHEMICAL LIME WEIGH FEEDERS

Matrix Engineering provided the electrical and mechanical design for (2) new hydrated lime feed control systems for USEC’s water softening facility. Each new lime feed microprocessor control system operated a (33 -667) lb/hr weigh belt feeder, which monitors hydrated lime feed rates, and also a (50-1000)lbs/hr lime slaker, which transformed the lime into a slurry to be pumped to aid in pH regulation of the plant’s process water. Each microprocessor control system involved configuring a set-point controller and SCR controller for each lime system to maintain consistent flow rates. Each control system also included a visual display for lime feed in pounds, feed rate, and alarm indication lights for upset feed conditions.

We also provided the mechanical piping design and implementation of the new hydrated lime feed equipment. New piping configurations were required to adapt the new lime feed equipment with the existing piping network. We provided a new adjustable structural support stand for both new lime weigh belt feeders to ensure each system was leveled true for proper function. Finally, new product inlet and discharge chutes with operator viewports were designed and implemented with the new lime feed equipment to prevent material buildup and bridging.

More Projects & News