MATRIX PROJECTS

CONTINUOUS REACTION CONVERSION PROCESS

Oct 20, 2001

Based on the success of the pilot plant design, Matrix Engineering provided the structural, mechanical and electrical engineering necessary for installing continuous reactors in phases while removing existing batch reactors. The resulting reacted slurry is a thick, corrosive, sticky substance in which build-up on the reactor side walls was a major obstacle to engineer around. Our team worked very closely with RP on developing an acid feed system into the reactor that would accomplish continuous washing of the reactor side walls. Great care was also taken in the layout of the reactors so the reacted sticky slurry would fall through a large diameter (cleanable) chute directly into the dryer below. Included in this project was a dense phase pneumatic transporter for conveying alumina to receiving hoppers above the new reactors. The continuous reactors were installed and batch reactors removed so not to interfere with production of a sold-out product. Continuous reactor redundancy was installed in the initial phase to gain experience and determine reliability of the new process before fully committing to the new process. As confidence was gained in the new process the existing batch reactors were replaced with the new continuous design. This was an engineering challenge due to spatial constraints and design flexibility to utilize batch and continuous systems simultaneously. Eventually all of the batch reactors were replaced and they now operate solely on the continuous reaction process. Matrix Engineering has continued to improve on the original reactor design to the current 3rd generation continuous reactor.

More Projects & News

01 Dec, 2021

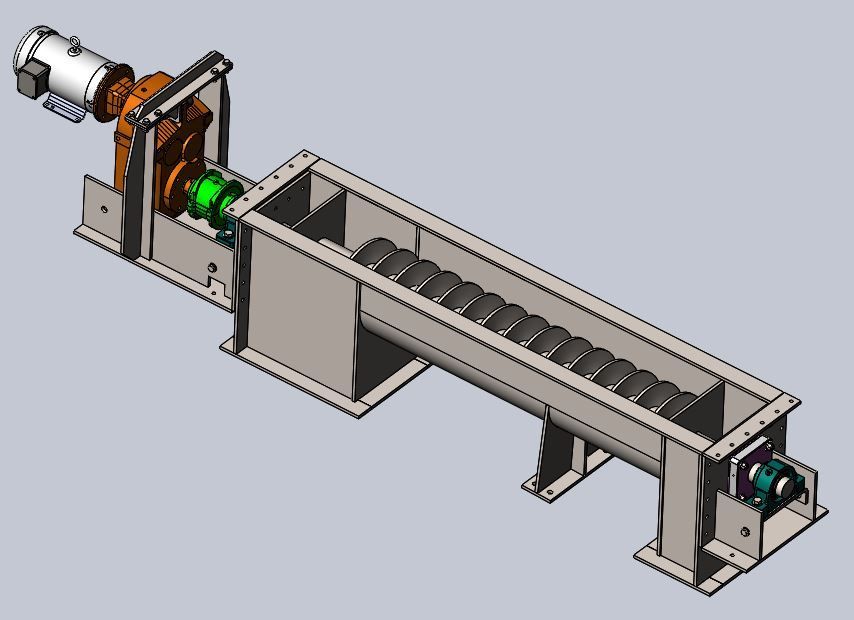

Matrix provided conceptual and hard mechanical design of a heavy duty screw feeder for metering phosphorus pentoxide (crystallized phosphoric acid) into a dissolve tank. Due to the hot reaction during hydration in the tank (resulting into very hot phosphoric acid) the variable speed screw feeder consisted of a 316L S/S 12 inch diameter auger and 1/2 inch thick trough. A special dump hopper with automated closing lid was designed with a large grated opening and bypass chute at the inlet of the feeder. Very special design considerations were made for protecting the conveyor seals and bearings from making contact with the hot acid. Our design allowed the acid crystals or hot liquid to fall out into an isolated gap and into the tank before it challenged the seal. This was a highly successful design has virtually eliminated the huge stock piles of drummed feedback material that accumulated due to the inability to dissolve the crystallized acid safely.

By Darren Jarvis

•

03 Jan, 2021

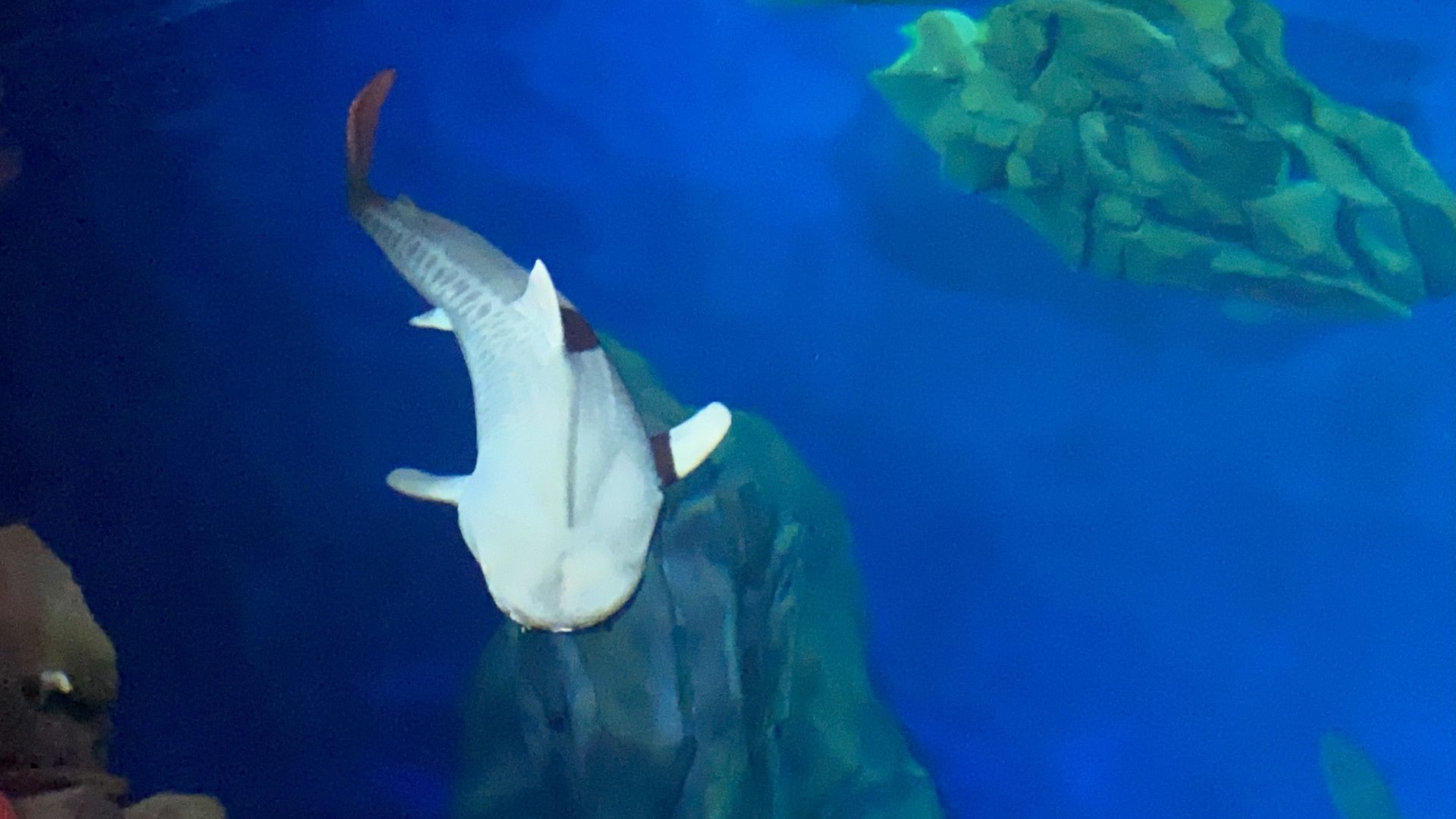

Matrix Industrial Systems was proud to work in conjunction with AC Marine in designing and supplying critical systems for Georgia Aquarium's newest venue to experience sharks directly with the grand opening of their 1.2MM gallon Shark Tank. This attraction allows you to submerge into the tank within a shark cage and begin an underwater journey traversing the pool as it is suspended and moved by a hoist/monorail system. Breathing air for the participants is supplied through an umbilical tethered to the cage and connected to a specialized Breathing Air Control System (BACS). Matrix supplied and installed this system with its umbilical as a turnkey project. Matrix and AC Marine were proud to be guinea pigs (or should I say SHARK BAIT) on the maiden voyage!

Site Map

Contact Info

112 Walter Jetton BlvdPaducah, KY 42001, United States

Website Design & Hosting by Arterburn.com