Projects

Water Treatment

A general description of this category of projects.

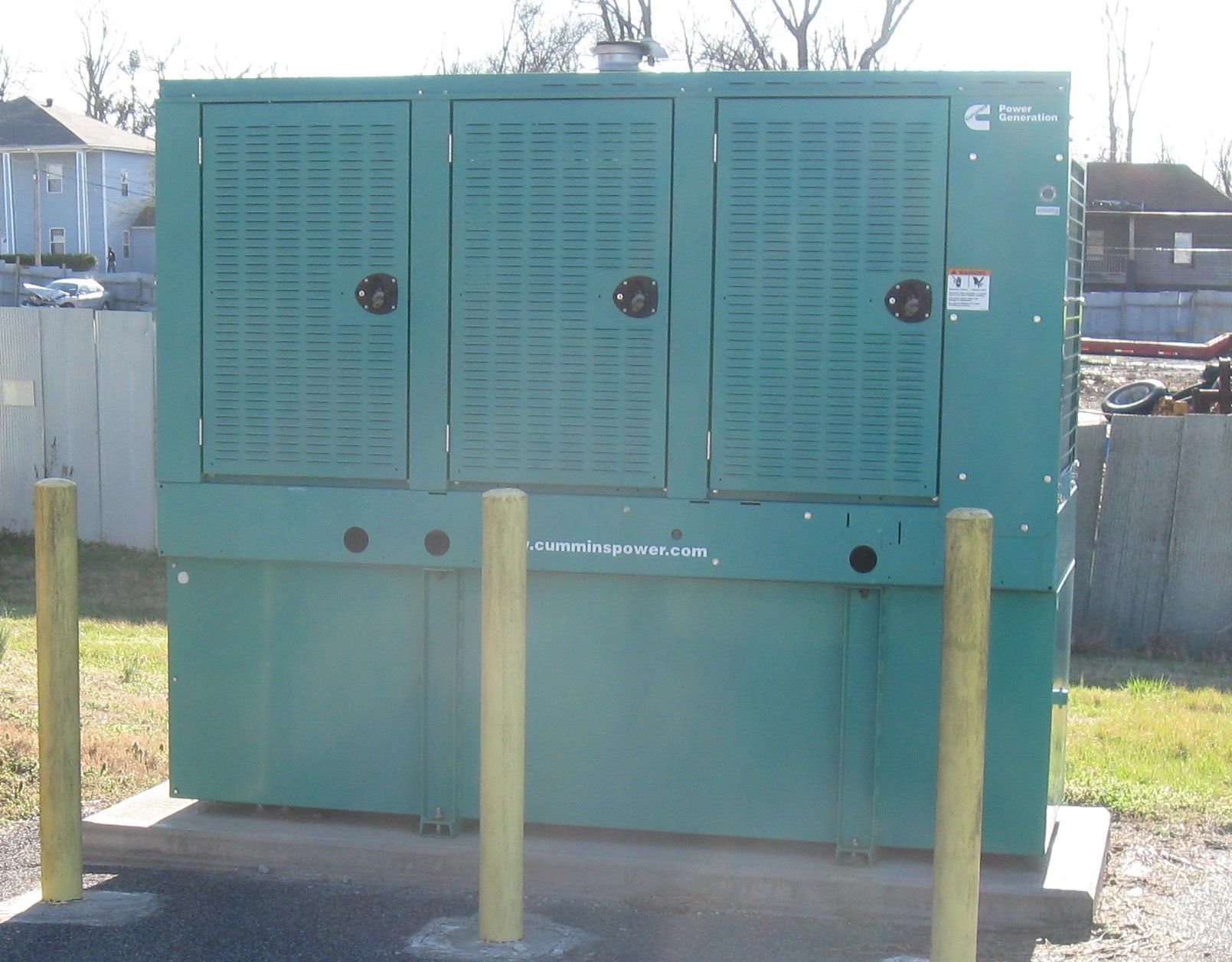

Our engineers provided electrical and controls engineering necessary to change out the existing electrical service, motor control center, and control system for the Paducah McCracken Joint Sewer Agency. We provided engineering and equipment necessary to provide temporary power and controls during construction to minimize downtime. Matrix also provided all PLC programming as well as construction management and startup services. In addition to the controls, Matrix also re-designed the en try of waste into the station and added a Muffin Monster.

Matrix provided the controls engineering for a wastewater treatment plant expansion. The expansion consisted of four new PLC control cabinets tied together on an Ethernet network. These PLC’s monitored and controlled new equipment in four different sections of the plant. The entire plant is monitored by a PC based SCADA system developed by Matrix.

Matrix provided the civil, structural, mechanical, electrical and controls engineering for a water softener system supplying the boilers at the Nashville, Tennessee facility. The system consisted of a packaged softener system and two brine tanks. Special considerations were made in the concrete design due to the strong salt water issues. PVC piping was used along with heat tracing for freeze protection. Matrix also integrated the controls between the packaged softener system and the brine pumping system.